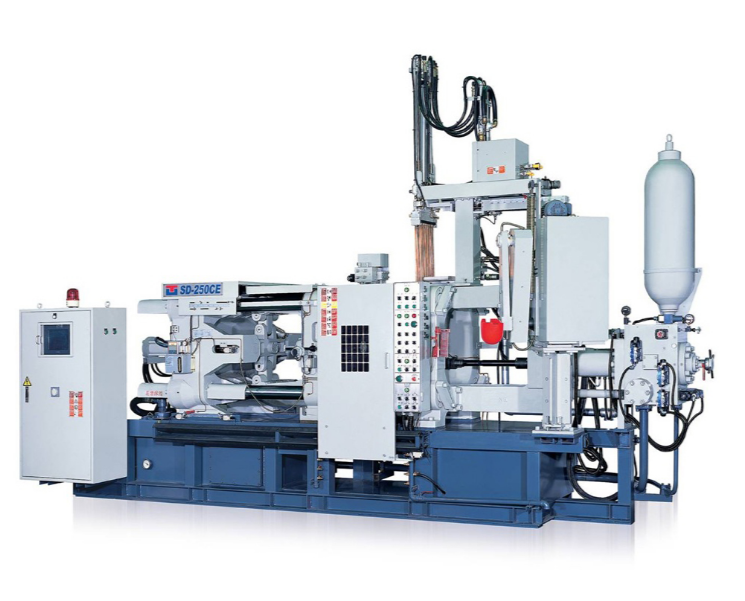

Pressure Die Casting

Holisticly brand sustainable solutions rather than clicks-and-mortar applications.

Phosfluorescently whiteboard fully tested initiatives.

Pressure Die Casting

High production efficiency & speed.

Produces complex & detailed parts with high accuracy.

Strong, lightweight parts with excellent surface finish.

Minimal material wastage

Suitable for mass production

The Pressure die casting process offers the greatest flexibility and the most cost-effective tooling. The advance equipment and the automatic loop line in foundry technology with skilled experienced workforce, we are able to adopt in quantity. We are able to cast different grades of aluminum alloys to fulfill customer specific requirements.

Fettling & Heat Treatment

RVGUPTA MACHCAST PVT LTD's machining services offer numerous benefits to our clients:

- Manual to semi-automatic way of fettling ease to attain the required surface finish and the profile dimensions of the cast components for further process. Shot blasting is one of the short processes but plays a significant role in enhancing the aesthetic look of the casting and also improves the stress properties of the part.

- The heat treatment of the Aluminum alloy is done to enhance the mechanical properties of the components. In-house facility shortens the delivery time and ensures metallurgical quality.

.jpg)

.jpg)